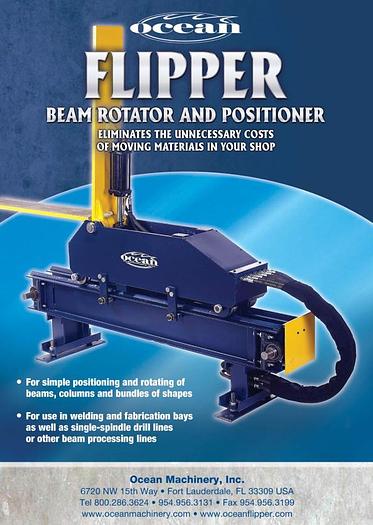

OCEAN FLIPPER BEAM ROTATOR & COLUMN POSITIONER

OCEAN FLIPPER BEAM ROTATOR & COLUMN POSITIONER

Description

Beam Rotator – Column Positioner the Easy Way The Ocean Flipper Beam Rotator Column Positioner is a simple and unique material handling component, that was originally designed to fit within the material support tables of the Ocean Avenger and other single-spindle drill lines, or other types of steel processing equipment where turning and positioning of profiles is required. The Flipper Beam Rotator Column Positioner reduces the demand on the overhead cranes, leaving this valuable resource free to move other items while the Flipper rotates beams on the Avenger. On a single-spindle drill line, the Ocean Flipper can rotate large and heavy beams and columns, and positions them up to the datum blocks in order to drill the different faces (top flange, bottom flange and web) without the need for an overhead crane or other lifting device and without any additional labor to assist with manual flipping and positioning. When used in conjunction with the Ocean Avenger CNC Drill Line, the Avenger Hydraulic power supply can be used, saving the cost of purchasing the optional hydraulic power unit. Despite being designed for single spindle drills, many Ocean Flippers are used purely as a beam rotating resource to speed up welding tables, where much time is lost waiting for an overhead crane to rotate a beam

Specifications

| Manufacturer | Ocean Machinery |

| Condition | New |

| Maximum Profile Size | 36″ (914mm) |

| Flipping Capacity | 26,000 lbs (11,800kg) |

| Working Height | 35″ +/- 1.5″ (890mm +/- 38mm) |

| Electrical Requirement | 110V Single Phase |

| Electrical Requirement (for optional hydraulic unit) | 230V/460V 3-Phase |

| Hydraulic Power Requirement (if customer supplied) | 1,200 – 2,500 psi, 15GPM Minimum |

| Hydraulic Tank Size (if customer supplied) | 15 Gallon tank min per pair |