KBS 621

KBS 621

or

Call 804.598.1780

Description

Mitering band saw for light- and medium-duty steel fabrication and service centers

Workspace 90° [mm]: 620 x 500

Benefits at a glance

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

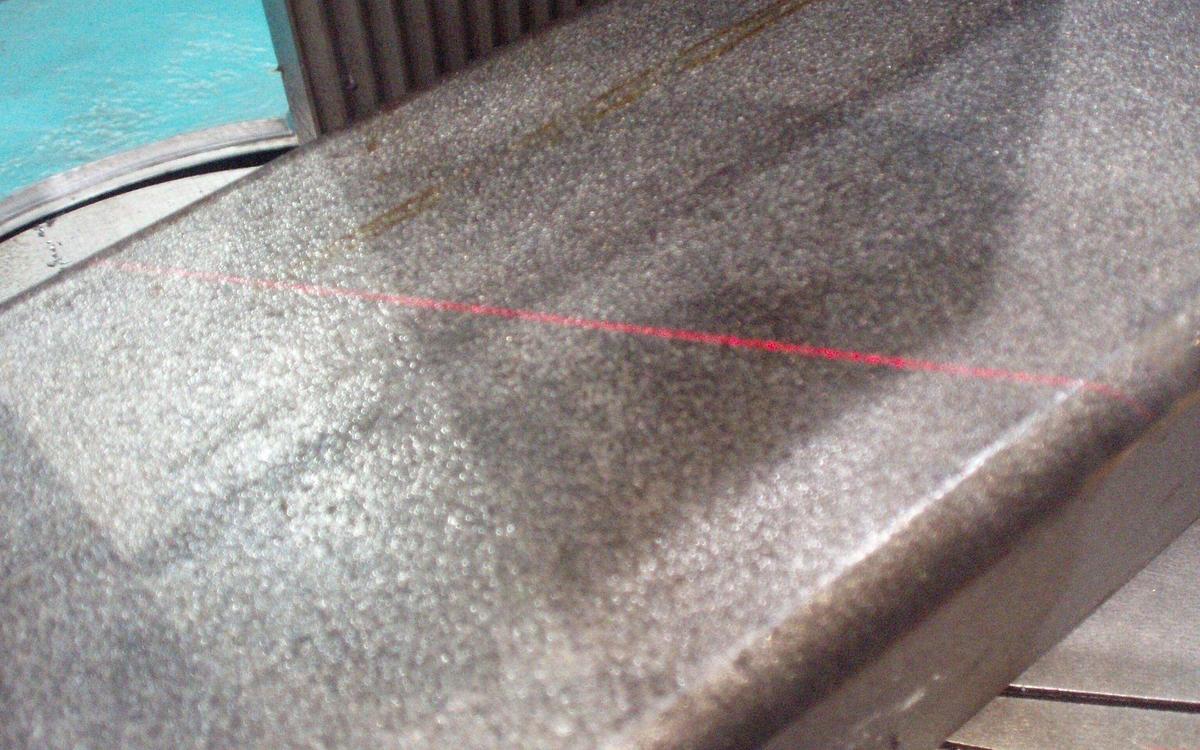

- Laser-assisted cutting edge visualisation for manual cuts

Features

- Powerful feed

- Fast and easy feed adjustement even during runtime

- Precise angle setting for high quality cuts

- NC-standard enables highest reliability

- Clamping directly next to operation area

- Low vibrations for long saw band lifetime and low operating costs

- Cutting of material layers and bundles possibles

- Automatic switching from rapid feed approach to pre-set feed rate

- Low idle times and higher machine utilization

- Feature is fully independend from machine program

- Automatic feed control based on band pressure detection

- Extended saw band life time based on material and band status

- Set the right tension level for a cutting process

- High tension is activated during cutting process

- Low tension during idle time for long band lifetime

- MQL ensure longer saw band lifetime

- No lubrications rest on the material possbile

- Less contamination of the machine and its environment

- Higher cutting performance

- Less wear on saw band for longer lifetime and lower costs

- Rotation speed measurement of both saw wheels

- Slippage is reliable detected

- Cutting process is stopped automatically

- Fast and powerful cuts for single beams as well as material layers or bundles

- Shortest processing times for high tonnages

- High cutting performance and precision

- Longlasting construction for long investment cycles

- Inclined saw band for higher average feed rates

- Automated chip handling

- Higher comfort for operator

- Parts can be programmed, imported and nested in the office

- Real time feedback of production status

- Automatic detection of band deflection

- Sensor results will be shown to the operator

- Maintenance can be executed according to real machine conditions

- Laser projection for manual cuts

- Transport system control directly on machine portal

- Lowering of machine base reduces collision risk when new material comes in

- Less wear on clamping unit and cutting table

Software

PROFICUT

Modern Software Package for KALTENBACH Sawing Machines

PROFICUT

Easy, user friendly machine operation

- Programming of orders via color touchscreen with large keypads directly on the machine control console

- Storage possibility for as many sawing orders as desired

- Automatic calculation of cutting speed and feed over the material group or DIN-Nr. (steel key)

- Graphical representation of the material

- Machine operation

PROFICUT

Profile database

- Comprehensive profile database

- Easily expandable

- Graphic display of workpiece forms

PROFICUT

Production data report

- Recording of production times of individual pieces or entire orders

PROFICUT

Data transfer and data response

- Data input directly on the machine control console

- Data import in DSTV or DSTV+ format

- Data export of previously produced parts in DSTV feedback format to any directory

Downloads

Flussdiagramm_Proficut_en (PDF, 0.03 MB)

Complementary

- Drilling machine for drilling, tapping, countersinking, marking and milling

- Powerful motors for high performance applications

- Processing on up to 3 axis simultainelsly

- Automatic tool change with up to 5 tools per axis

- Integrated material measurement system for high presicion

Specifications

| Manufacturer | KALTENBACH |

| Condition | New |