KBS 1010

KBS 1010

or

Call 804.598.1780

Description

Mitering band saw for light- and medium-duty steel fabrication and service centers

Workspace 90° [mm]: 1,010 x 500

Benefits at a glance

- Long saw band life

- Best cutting quality

- Robust, low-vibration design

- Perfect cutting results

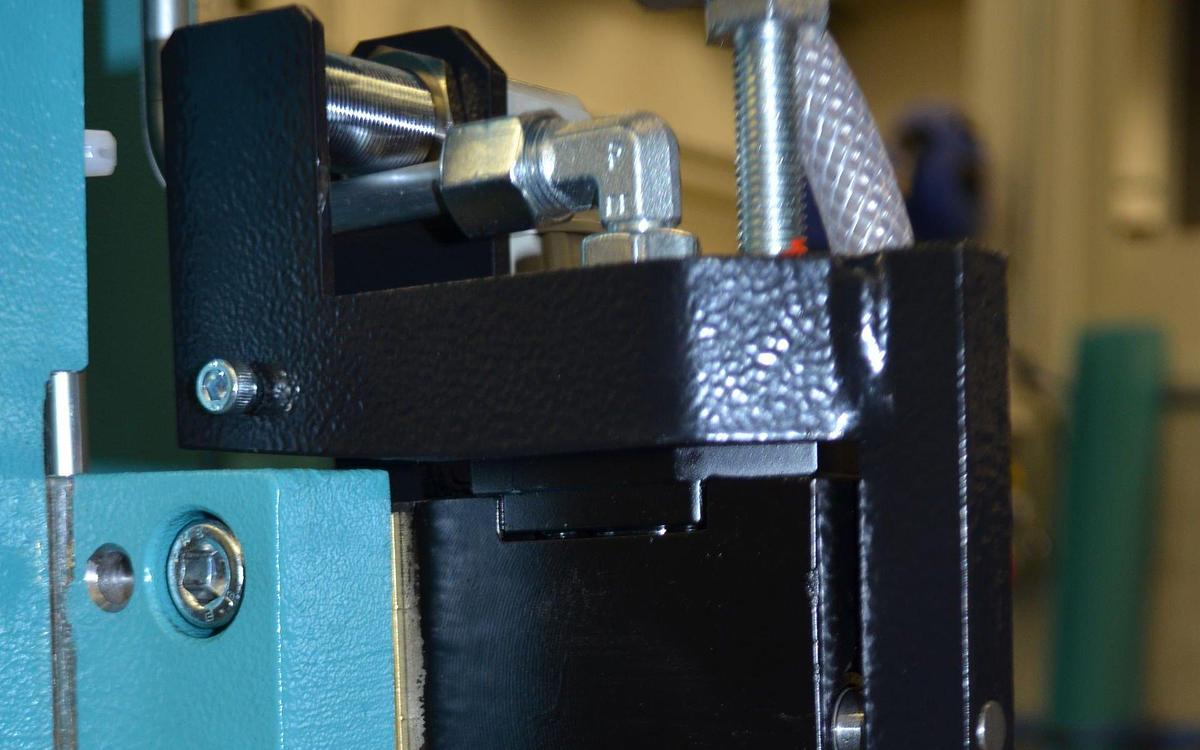

- Solid, reliable clamping system

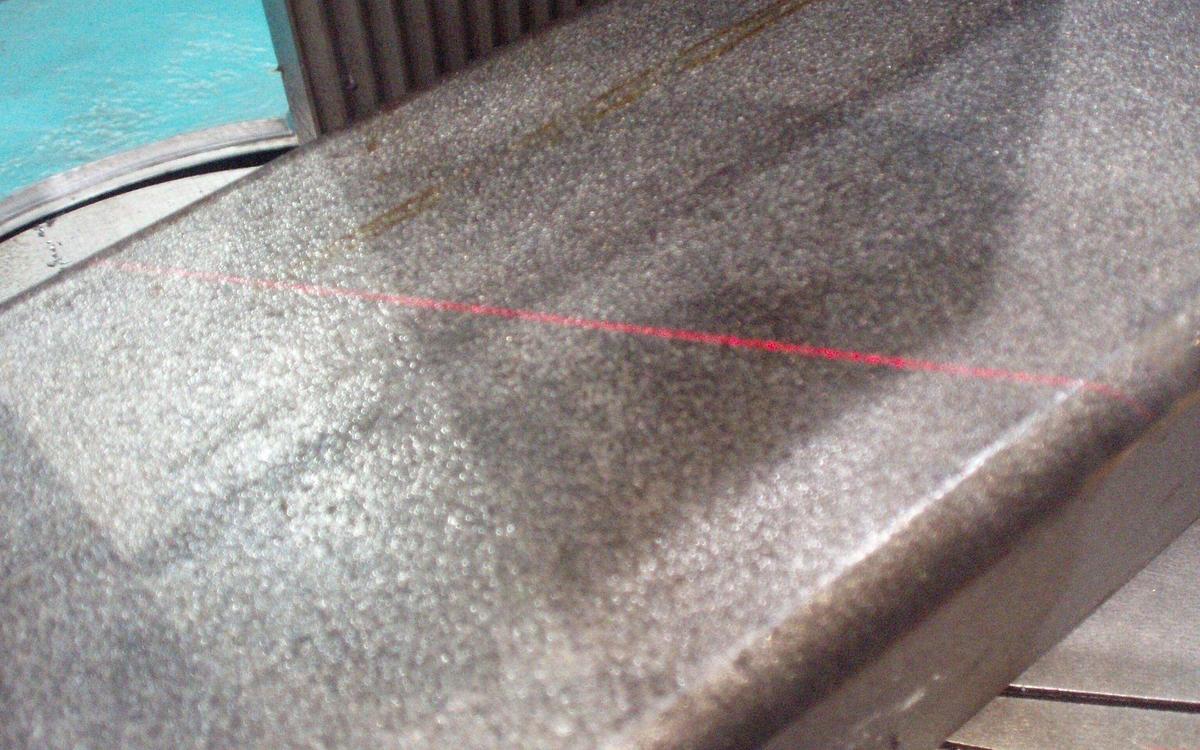

- Laser-assisted cutting edge visualization for manual cuts

Features

- Powerful feed

- Hydraulic feed control with monitoring

- Fast and easy feed adjustement even during runtime

- Automatic switching from rapid feed approach to pre-set feed rate

- Low idle times and higher machine utilization

- NC-controlled angle setting

- High quality cuts

- NC-standard enables highest reliability

- Horizontal and vertical clamping device

- Low vibrations for long saw band lifetime and low operating costs

- Cutting of material layers and bundles possible

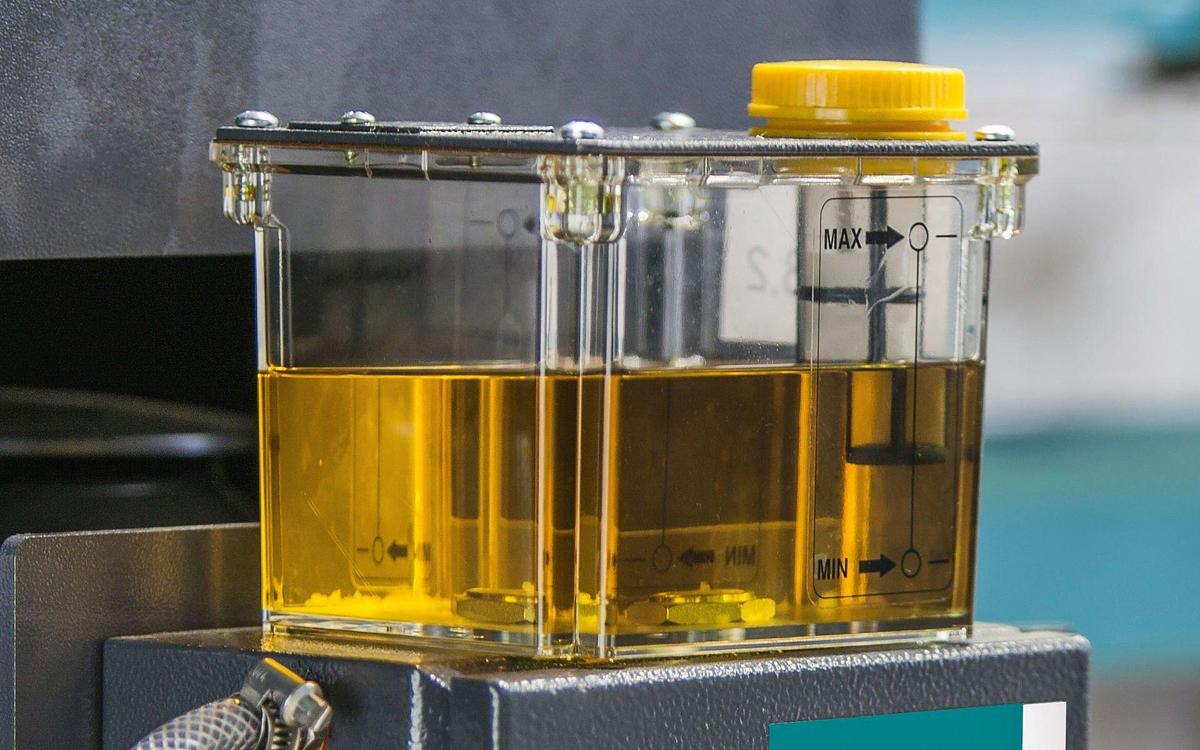

- Minimum quantity lubrication

- Longer saw band lifetime

- No lubrications rest on the material

- Heavy feed gripper with horizontal hydraulic clamping device

- Positioning of lengths more than 3,000 mm via multiple stroke system

Software

PROFILINE

Modern Software Package for KALTENBACH Drilling and Drilling-Sawing Machines

PROFILINE

Easy, user friendly machine operation

- Programming of orders via color touchscreen with large keypads directly on the machine control console

PROFILINE

Order manager

- Create, copy and delete orders

- Graphic display of individual positions within an order

PROFILINE

Profile database

- Comprehensive profile database

- Easily expandable

- Graphic display of workpiece forms

PROFILINE

Tool manager

- Tool Changer setup based upon the tool type and diameter

- Allocation of the drill diameter to rotational speed settings and feed rates

PROFILINE

Production data report

- Recording of production times of individual pieces or entire orders

PROFILINE

Data transfer and data response

- Data input directly on the machine’s control console

- Data import in DSTV or DSTV+ format

- Data export of previously produced parts in DSTV feedback format to any directory

Downloads

Flussdiagramm_Profiline_en (PDF, 0.03 MB)

Complementary

- Drilling machine for drilling, tapping, countersinking, marking and milling

- Powerful motors for high performance applications

- Processing on up to 3 axis simultainelsly

- Automatic tool change with up to 5 tools per axis

- Integrated material measurement system for high presicion

- Drilling machine for drilling, tapping, countersinking, marking and milling

- Additional sub-axis for parallel processing on 500 mm along the material

- Powerful motors for high performance applications

- Processing on up to 3 axis simultainelsly

- Automatic tool change with up to 5 tools per axis

- Integrated material measurement system for high presicion

Specifications

| Manufacturer | KALTENBACH |

| Condition | New |