KDM 1015

KDM 1015

or

Call 804.598.1780

Description

Drill line for light-, medium- and heavy-duty steel fabrication and service center

Workspace [mm]: 1,000 x 500 and number of tools: 15

Benefits at a glance

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful drive for highest processing performance

- Powerful clamping system for a longer tool usage

- Intelligent material measurement for greater process reliability

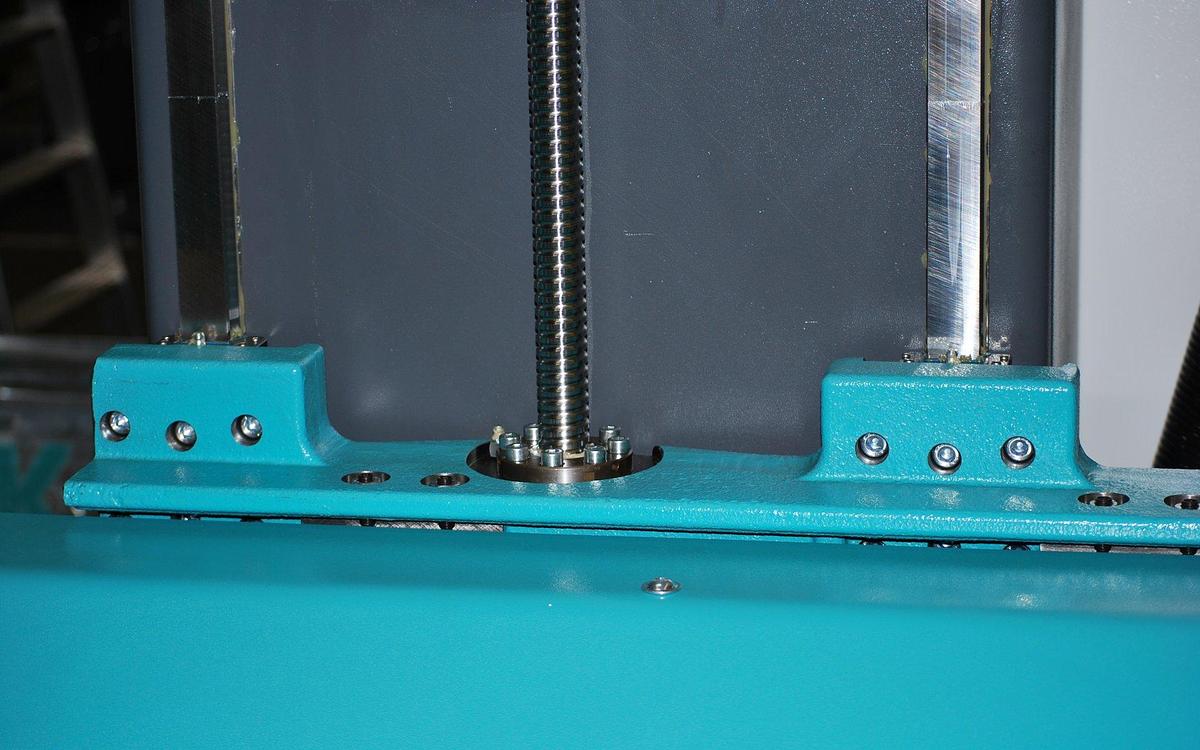

- Servomotors and ball screw for high-precision

- Tool changer for 5 tools per axis for less setup times

Features

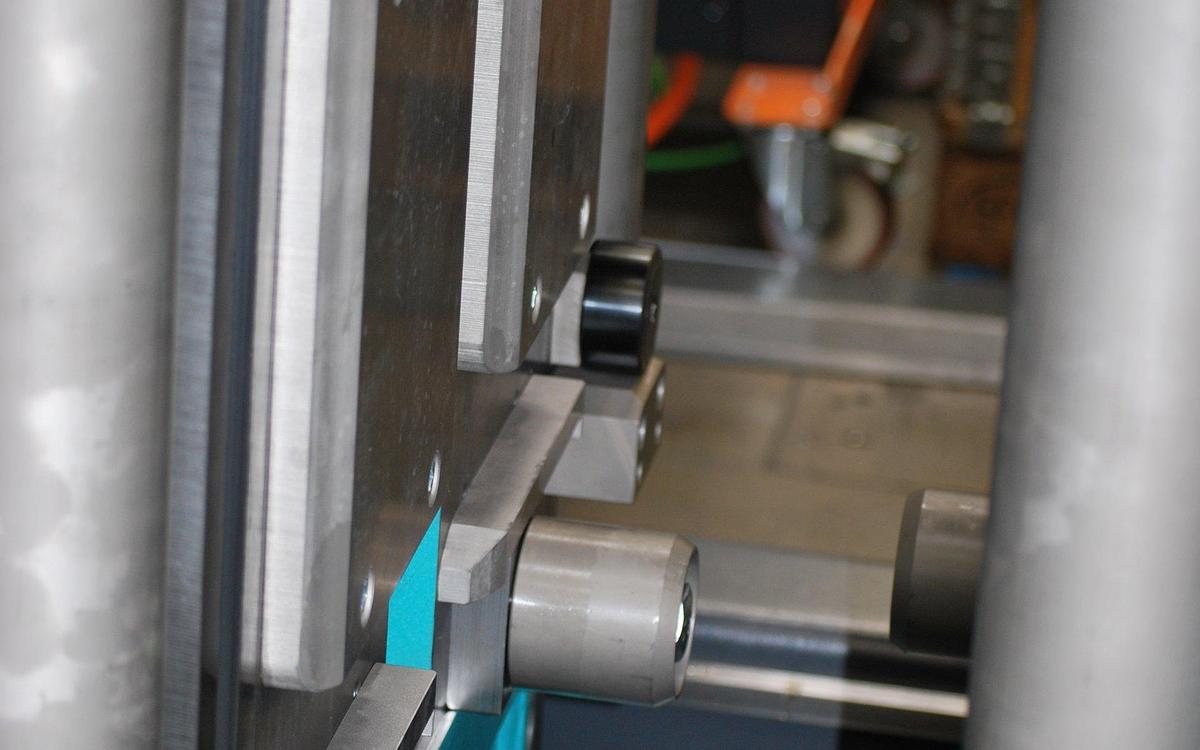

- High rigidity ensures low vibrations for low operational costs

- Very long machine lifetime even under challenging conditions

- Robust design for low vibrations and less tool wear

- Fast and precise positioning via ball screw drive and servomoters

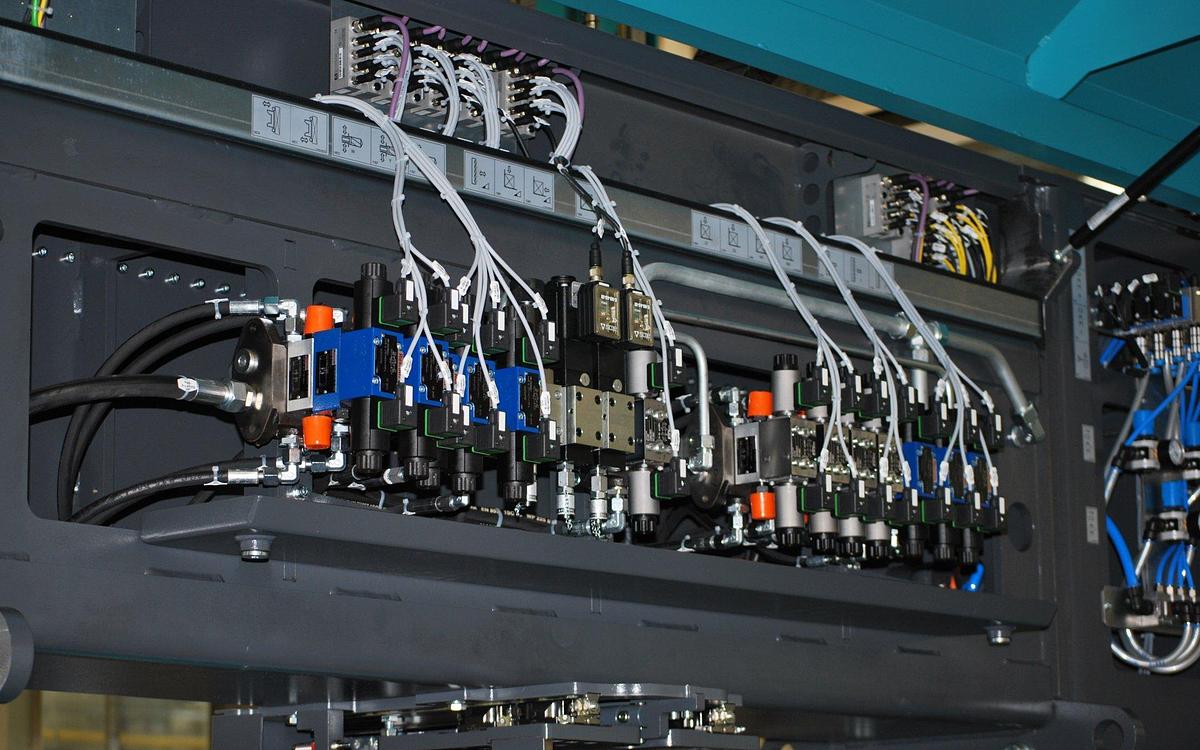

- Horizontal and vertical clamping system for less vibration

- High clamping power for best fixation and precision

- Less tool wear and thus operational costs

- Provided Technologies are drilling, milling, tapping, countersinking and marking

- Powerful and fast processing

- Outstanding drilling performance

- Fast tool changer for 5 tools per axis

- Low setup time for higher machine utilization

- Automatic tool length measurement

- Integrated chip container in machine base

- Easy chip handling

- Extractable on both side for full flexibility

- Automated chip handling

- Higher comfort for operator

- Fast marking of numbers and letters

- Mark up to 21 letters without material movement in parallel

- Marking is also visible after shotblasting and painting

- Fast and flexible marking for characters and geometries

- Marking on up to 4 material sides

- Powerful milling features

- Easy operation due to milling macros

Software

PROFILINE

Modern Software Package for KALTENBACH Drilling and Drilling-Sawing Machines

PROFILINE

Easy, user friendly machine operation

- Programming of orders via color touchscreen with large keypads directly on the machine control console

PROFILINE

Order manager

- Create, copy and delete orders

- Graphic display of individual positions within an order

PROFILINE

Profile database

- Comprehensive profile database

- Easily expandable

- Graphic display of workpiece forms

PROFILINE

Tool manager

- Tool Changer setup based upon the tool type and diameter

- Allocation of the drill diameter to rotational speed settings and feed rates

PROFILINE

Production data report

- Recording of production times of individual pieces or entire orders

PROFILINE

Data transfer and data response

- Data input directly on the machine’s control console

- Data import in DSTV or DSTV+ format

- Data export of previously produced parts in DSTV feedback format to any directory

Downloads

Flussdiagramm_Profiline_en (PDF, 0.03 MB)

Complementary

- Fast and accurate saw for big profiles

- Cutting mitering angle up to +45°/-60°

- Vertical and horizontal clamping device for low vibrations

- Automatic feed control and slippage detection for highest comfort

- Fast and accurate saw for big profiles

- Cutting mitering angle up to +50°/-60°

- Powerful drive for carbide saw bands to reduce cutting times up to 50%

- Highest automation potencial for less manpower requirements

- Intelligent material measurement for highest precision and process reliability

- Vertical and horizontal clamping device for low vibrations

- Automatic feed control and slippage detection for highest comfort

- Precise positioning of material

- Adjustments for the processing of layers possible

- Automated outsorting of short parts

- Handling of parts with straight cuts

- Up to 2 outfeed positions

- Automated outsorting of short parts

- Handling of parts with mitered cuts

- Up to 3 outfeed positions

- Automated outsorting of short parts

- Handling of parts with mitered cuts

- Up to 6 outfeed positions

Specifications

| Manufacturer | KALTENBACH |

| Condition | New |