KF 2114 / 28

KF 2114 / 28

or

Call 804.598.1780

Description

Plate processing centre for complete steel processing from one single source

Workspace [mm]: 2,100 x 6,000 (optional 12,000)

Benefits at a glance

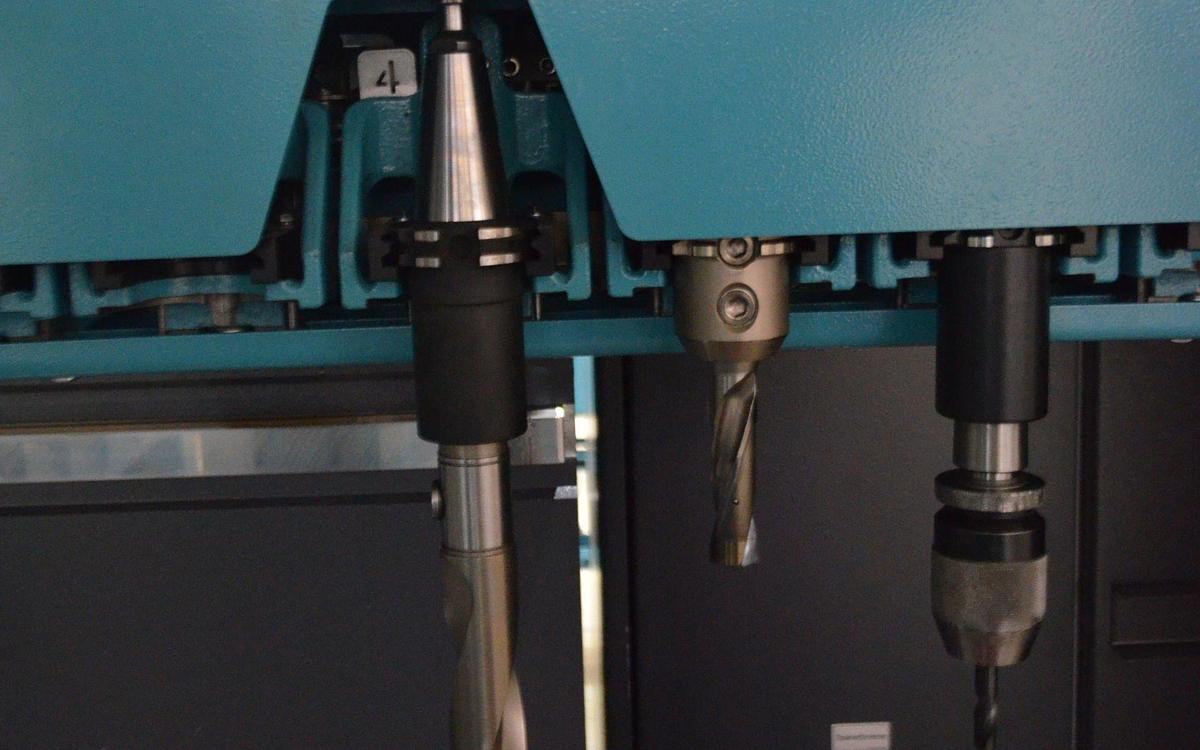

- Up to 2 drilling heads and plasma heads for maximum output

- Diverse manufacturing technologies

- Milling as standard function

- Powerful drives

- Maximum performance

- Optimal cutting quality

Features

- High cutting speed

- Optimum cutting quality

- System available in various capacity ranges

- Common cut and cross-cut technology for significantly less waste

- Various processing possibilities

- 7/14/28-place tool changer per axis

- Faster set-up times

- Automatic and reliable chip disposal

- Special brush removes swarf

- Reducing the risk of wear

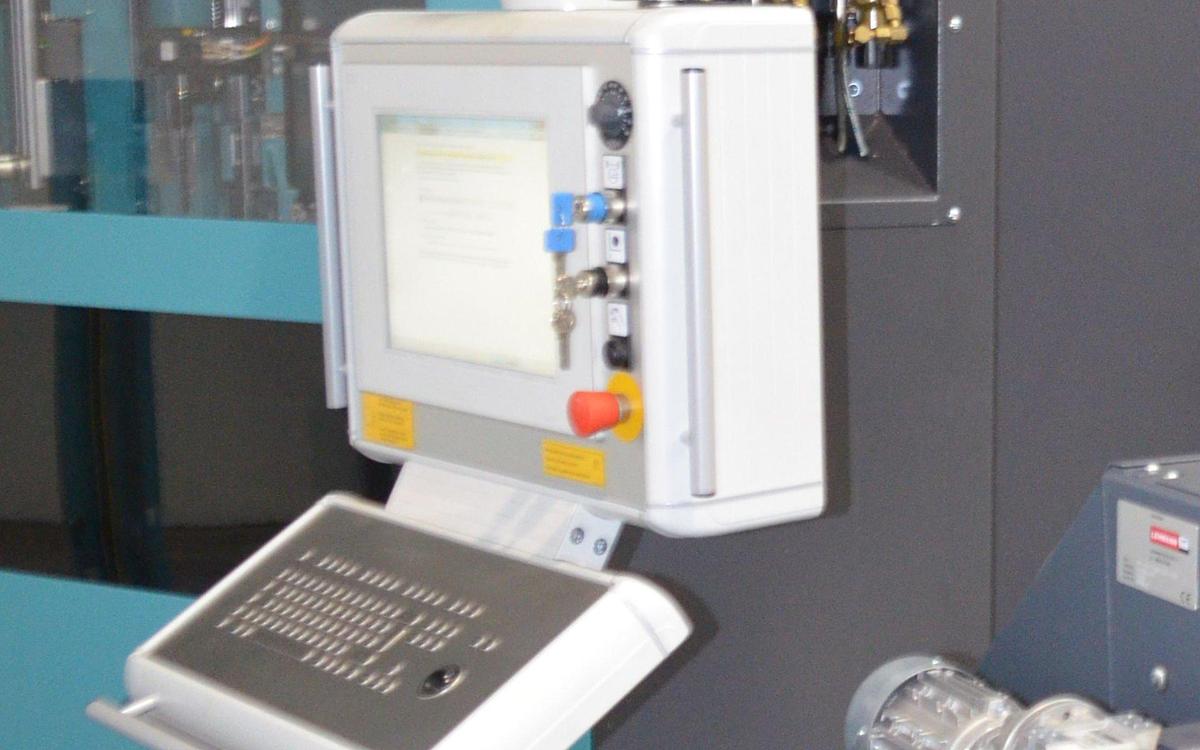

- Plain-text display of machine data and possible error messages

- Good observation of the processes

- Rapid intervention in case of disturbance

- Fast, high-quality marking process for applying letters/numbers

- Imprint still clearly visible after galvanizing or painting

- High processing performance

- Drilling, milling, thermal cutting, countersinking, tapping, graining, marking on one single machine

- First class end products

Options

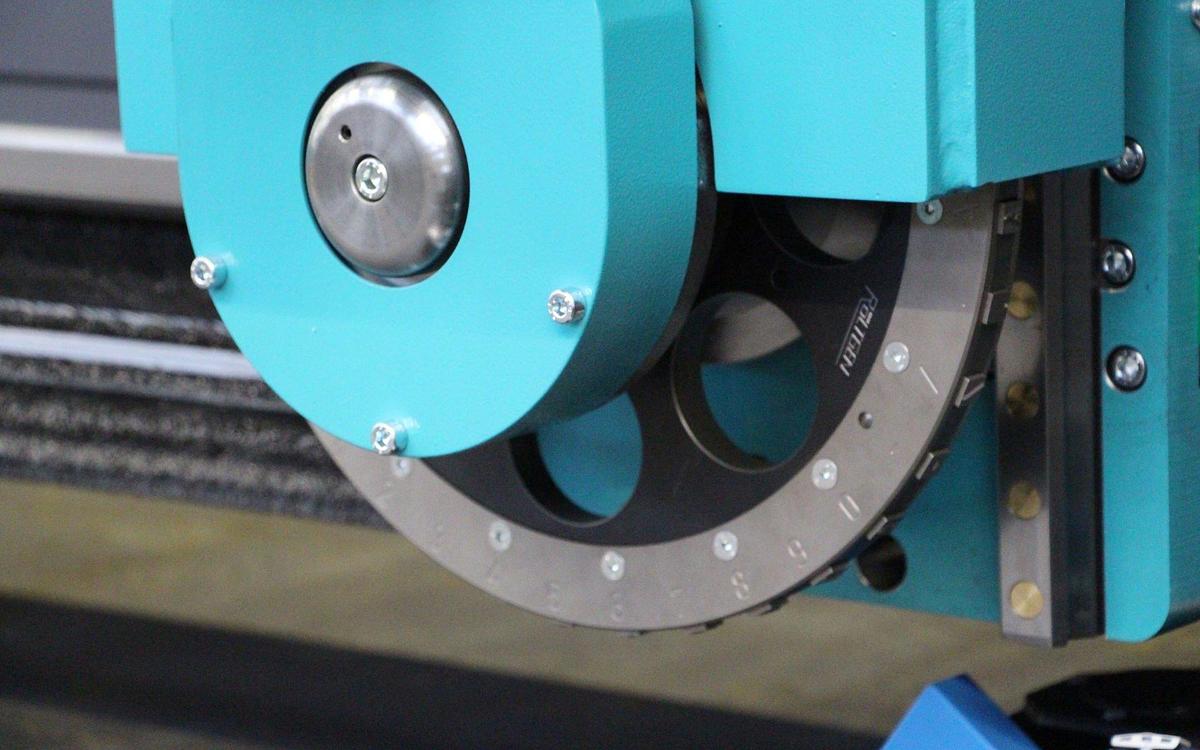

- Bevel angle ±52° in all directions

- Endless rotation with twist free hose package

- Servo controlled drives

- Low maintenance design

- Powerful drives

- Available in various capacity ranges

- Various bevel possibilities

- Optimum cutting quality

Software

Modern Software Package for KALTENBACH Plate Processing Machines

Easy, user friendly machine operation

- Color touchscreen with large keypads directly on the machine control console

Tool manager

- Tool Changer setup based upon the tool type and diameter

- Allocation of the drill diameter to rotational speed settings and feed rates

LANTEK

Programming via macros integrated into the drawing program

- Macros available from within the integrated drawing program and can be individually created, modified or expanded

LANTEK

Cross-cut function

- Interactive automatic or manual true-shape nesting

LANTEK

Econo-cut function

- Interactive automatic or manual true-shape nesting

LANTEK

WOS Workshop Organization System

- On-screen information on the current and open nesting orders with plate data, estimated amount of processing time, tools, etc.

- Recording of actual processing time

- Information on the production status

LANTEK

Data transfer and data response

- Data input directly on the machine’s control console

- Data import in DSTV, DXF or DWG format

- Data export of already produced parts in any directory

Downloads

Flussdiagramm_Lantek_en (PDF, 0.03 MB)

Complementary

- Carriage

- Cross transport with lift-and-carry system

Specifications

| Manufacturer | KALTENBACH |

| Condition | New |