PAXY Plate Processor

PAXY Plate Processor

or

Call 804.598.1780

Description

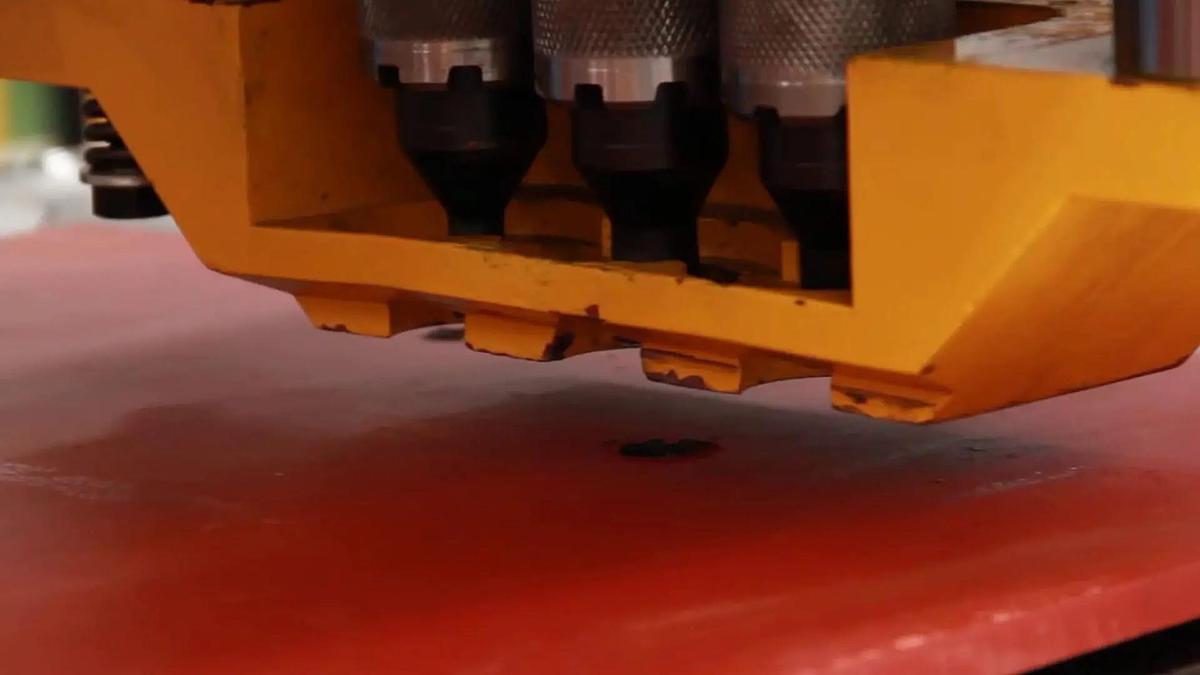

The PAXY series from GEKA offers automated punching, marking, and drilling of steel plates with high precision and speed. Its robust frame and servo-driven axes ensure accurate positioning, while the punching unit can be configured with up to three selectable punches.

With a CNC control and intuitive software, the PAXY is ideal for manufacturers needing flexibility and repeatability. Available in various sizes, it suits sectors like steel construction, heavy fabrication, energy, and infrastructure.

- Rigid steel structure with precision ball screws for both X and Y axes.

- Independent servo drives for each axis with encoder feedback.

- Dual gripper guides ensure plate stability during movement.

- Accurate and fast positioning for all programmed coordinates.

- Hydraulic punching unit with up to 220 tons of force.

- Configurable with up to 3 independent punches for high productivity.

- Central punch delivers 100% of the force; lateral punches receive up to 75%.

- Capable of punching diameters up to 40 mm (1 ½”) in plates up to 40 mm tck.

- 11 kW vertical drilling station.

- Compatible with ISO 40 tool holders.

- Max hole diameter: 40 mm (1-9/16”).

- External or internal lubrication system (MQL).

- Dual servo motor system enables fast and precise movement.

- Max axis speed: 34 m/min (1,339 in/min).

- Positioning accuracy of ±0.008 mm (±0.001 in).

- Compact layout for easy loading and unloading of metal plates.

- Integrated marking station with 10 interchangeable characters.

- Character size: 10 × 7 mm (⅜” × 5/16”).

- Controlled by CNC; activated automatically from the software.

- Marking is performed by hydraulic pressure on the rear of the plate.

- 15” industrial touch screen with integrated keyboard.

- Windows-based control system developed by GEKA.

- Includes Line Pro software for visual part programming and DXF/DSTV import.

- Multiple operation modes: run, design, jog, setup, alarm.

Specifications

| Manufacturer | GEKA |

| Condition | New |

| Max length of sheet X Axis | 1000 mm |

| Max length of sheet Y Axis | 500 mm |

| Punching force | 80, 110, 165 or 220 tons |

| Max traverse speed per axis | 24 m/min |

| Max combined traverse speed | 34 m/min |

| Positioning tolerance | 0.1 mm |

| Number of punches | 3 |

| Max central punch diameter | 40 mm |

| Max lateral punches diameter | 31 mm |

| Max through thickness central punch | 40 × 40 mm |

| Drilling unit | 11 kW |

| Tool holder | ISO 40 |

| Spindle speed range | 120–1500 rpm |

| Max drilling diameter | 40 mm |

| Max plate thickness | 40 mm |

| Marking unit | 10 characters |