DSB Drill & Saw Beamlines

DSB Drill & Saw Beamlines

or

Call 804.598.1780

Description

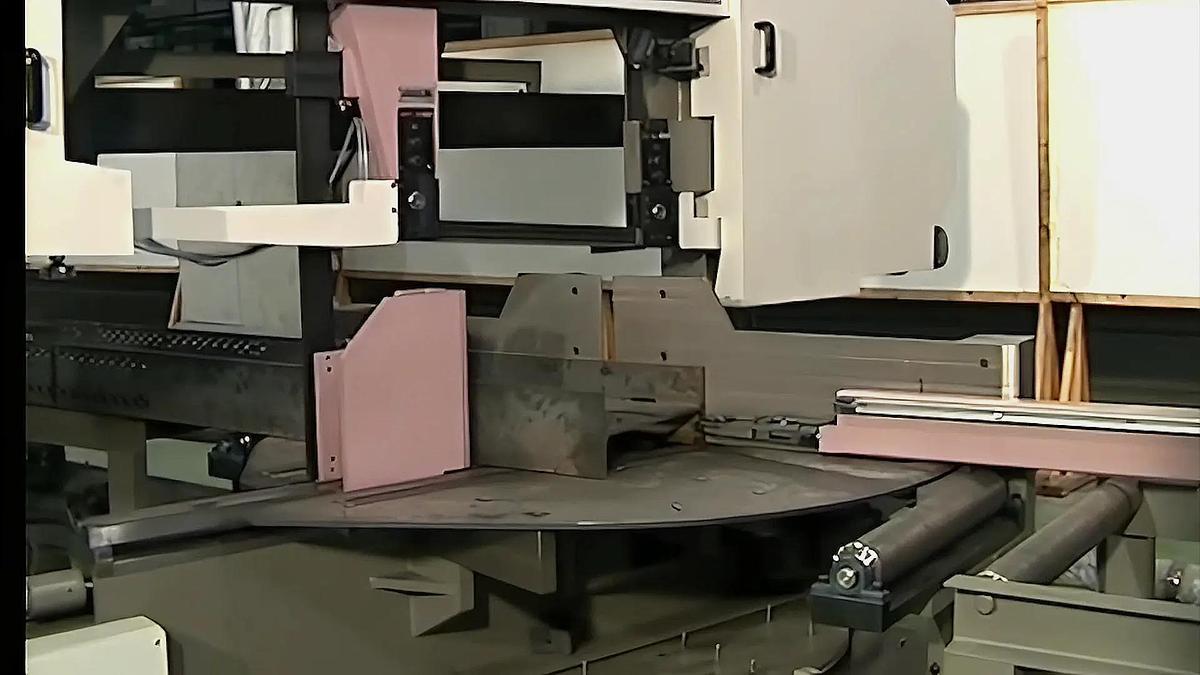

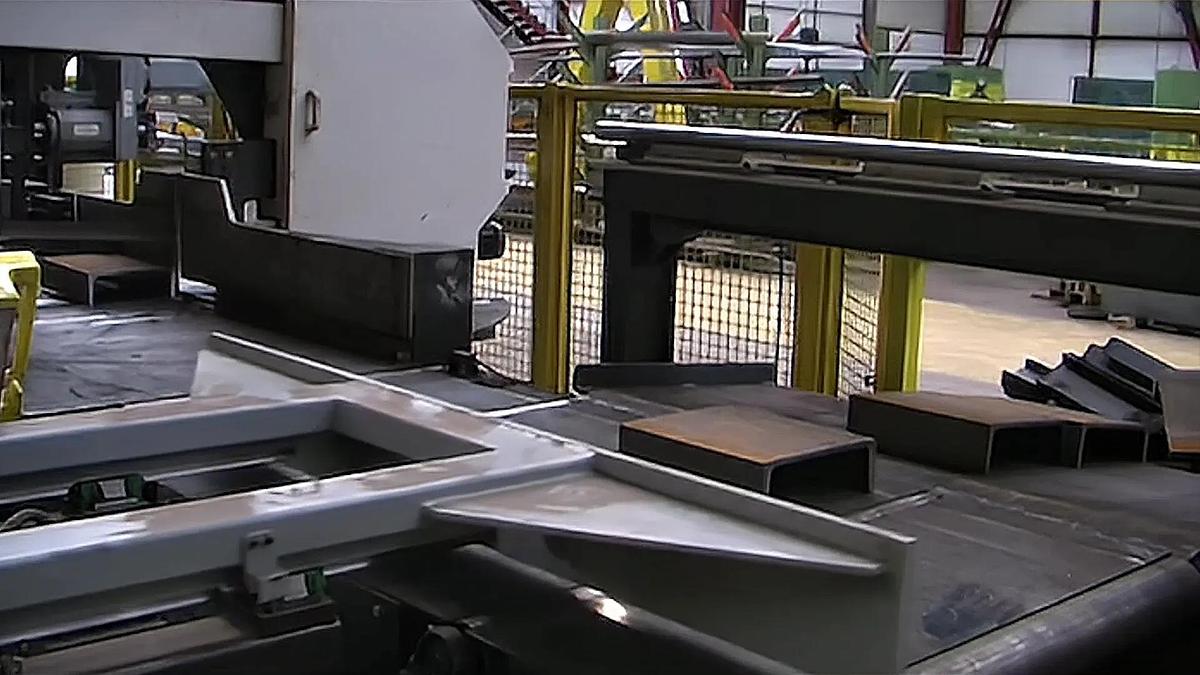

The DSB series are high-productivity beamlines for drilling and bandsaw cutting of structural profiles. These machines combine high-speed CNC drilling and precision bandsaw cutting in a single robust system. Designed to handle structural steel beams, c-channels, and profiles, the DSB lines optimize production by integrating drilling and sawing into one automated process.

3-SPINDLE DRILLING UNIT- 3 independent drill heads (2 horizontal + 1 vertical).

- Drilling, countersinking, tapping, and countherboring operations.

- Automatic tool change system.

- Laser calibration for automatic tool length detection.

- Automatic mitre cuts from +45º to -60º.

- Frequency inverter-controlled blade speed.

- Blade cleaning by motorized brush.

- Straight and mitre sawing without repositioning clamps.

- Horizontal and vertical hydraulic clamping.

- CNC-controlled feeding gripper with 14 m capacity.

- Manual 90º turning gripper.

- Infeed rollerway with vertical aligning rollers.

- Air-oil mist spray system with triple outlets.

- Clean and waste-free operation.

- External and internal tool cooling compatible.

- Laser tool calibration to avoid collisions.

- Laser detection of profile start.

- Automatic material width detection via clamps.

- Embedded Windows 10 OS.

- USB and Ethernet connectivity.

- Compatible with TEKLA, DSTV and other industry file extensions.

- Includes LANTEK FLEX 3D programming license

Specifications

| Manufacturer | GEKA |

| Condition | New |

| Max Workpiece Size | 400 x 300 |

| Max Cutting Capacity 90º | 700 x 500 |

| Saw Blade Dimensions | 6585 x 41 x 1.3 |

| Drilling Diameter | 6 – 40 |

| Saw Motor Power | 5.5 kW |

| No. of Drill Heads | 3 |