GT Angle Lines with Rack & Pinion Feeding

GT Angle Lines with Rack & Pinion Feeding

or

Call 804.598.1780

Description

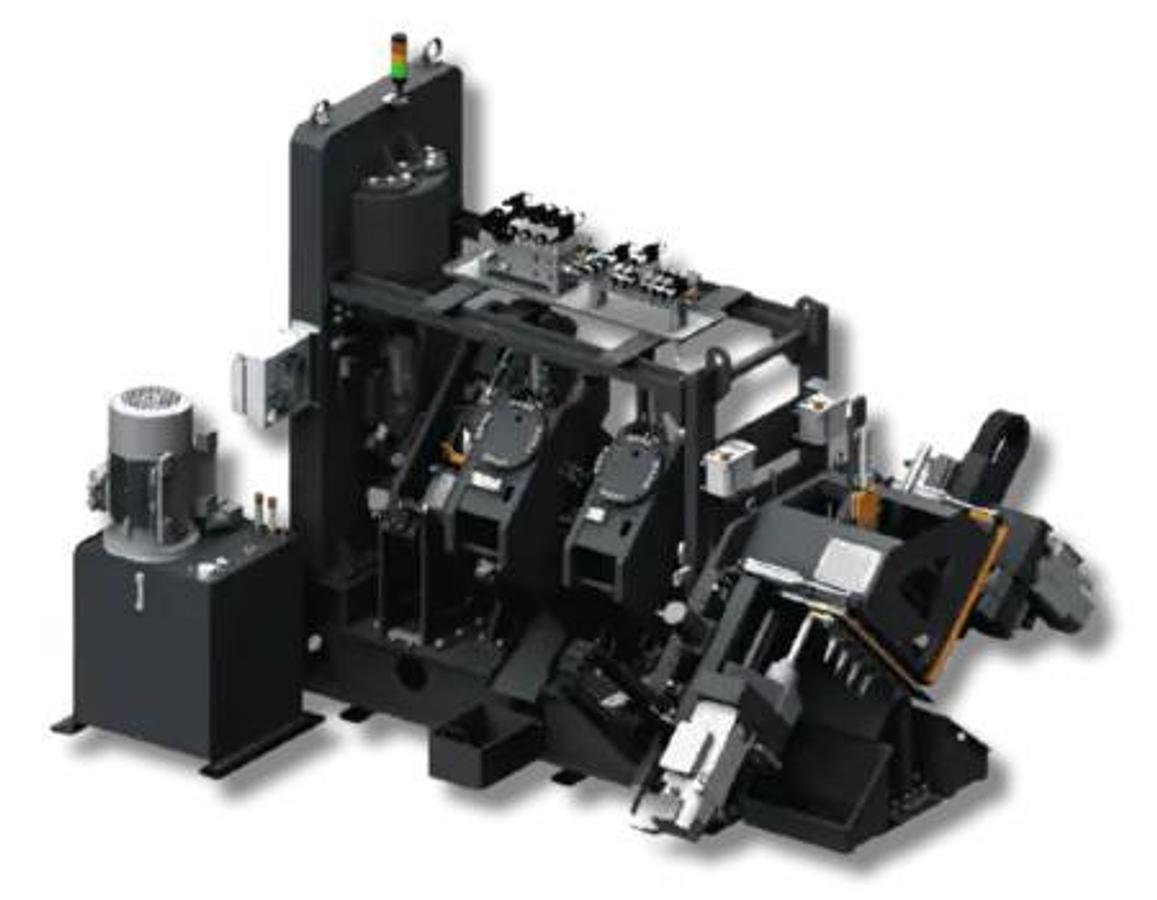

The GEKA GT series is an advanced marking, punching, drilling and shearing angle line designed for high productivity processing of angle profiles. With different models suitable for different productivity requirements, the GT range is the ideal choice for industries such as telecommunication towers, steel construction, and industrial manufacturing.

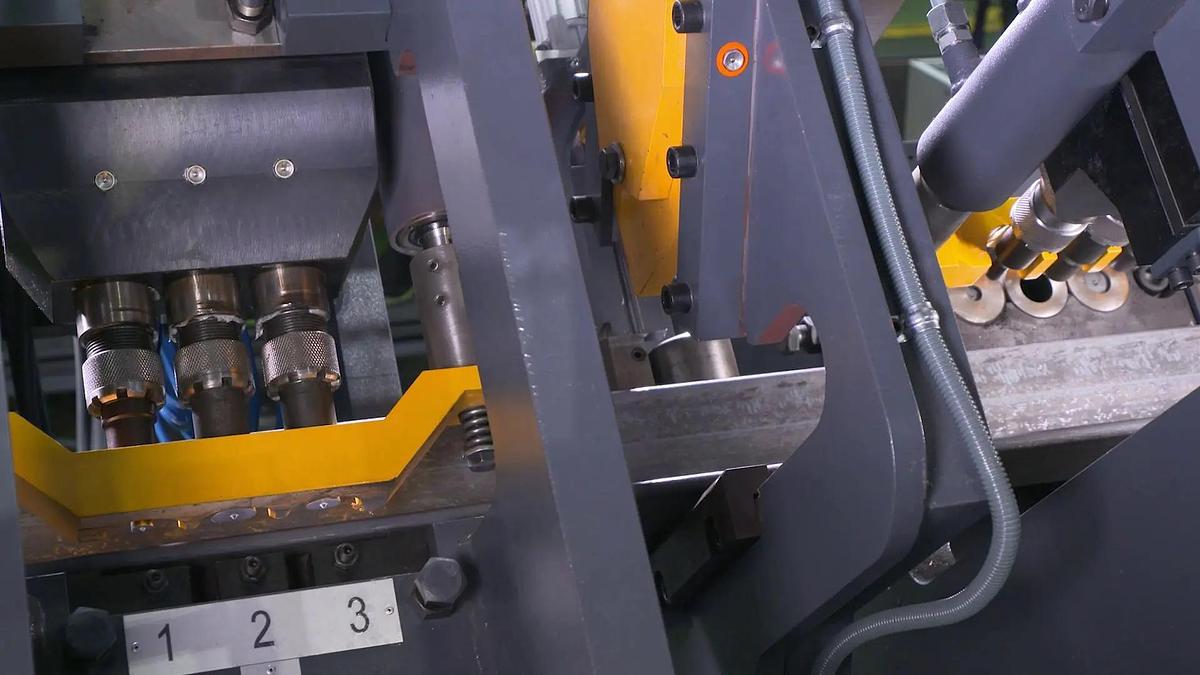

PUNCHING UNIT- Up to three punches per leg, providing high flexibility in production.

- Precise CNC control, with automatic positioning adjustment of the backmarks.

- Quick-change punch and die system, reducing tooling change times.

- 31-31-31 punching unit, allowing up to Ø31 mm punching in material thicknesses up to 15 mm.

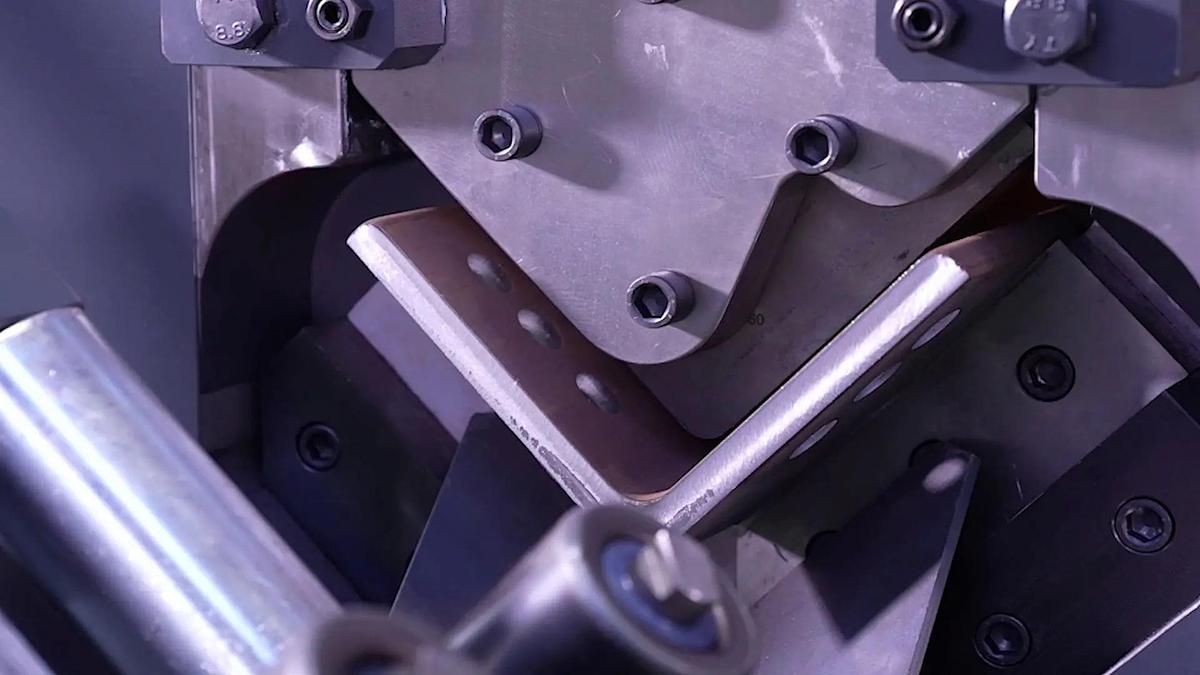

- No waste shearing station with capacity up to 560 tons.

- Quick-change blade system, with direct access to the knife holder.

- Precision angle shearing station, with adjustable stroke via CNC limit switches.

- Shearing capacity up to L-250x250x25 mm for angle profiles.

- Optional integrated disc-sawing station for profiles up to L-300x300x35 mm.

- Two powerful 9 kW drilling heads, one head per flange.

- Ø40 mm drilling capacity in different material thicknesses.

- ISO 40 tool holder system with internal lubrication.

- Automatic tool changer with capacity for 5 different tools.

- Rotary encoder measuring system, with 0.15 mm/m accuracy.

- Adjustable speed up to 60 m/min, optimizing processing time.

- Automatic loading system via chain-drag conveyors

- Automated material outfeed system, via motorized tilting tables.

- High-pressure hydraulic marking unit.

- Cassete marking system available with 5x character holders and up to 20x characters in each stroke.

- Wheel marking system also available, with 40 characters, via the shortest path selected by the CNC.

- Automatic backmark controlled via the CNC.

- PC Control Panel with Windows 10 and 15” touch screen.

- User-friendly interface, simplifying programming and project storage.

- USB and RJ45 network connectivity, enabling fast file transfers and remote support.

- Lantek Flex3D Steelwork: Punching, shearing, and drilling simulation, automatic collision detection, and material optimization.

Specifications

| Manufacturer | GEKA |

| Condition | New |

| Min. Angle Size | 35x35x4 |

| Max. Angle Size | 100x100x10 |

| Max. Flat Bar Size | 100x10 |

| C-Channel Processing | - |

| No. Punches per Leg | 2 |

| Max. Central Punching Diameter | 31 |

| Punching Power (tons) | 72 |

| Shearing Power (tons) | 130 |

| Material Infeed | Pincher |