GR Angle Lines with Roller Feeding

GR Angle Lines with Roller Feeding

Description

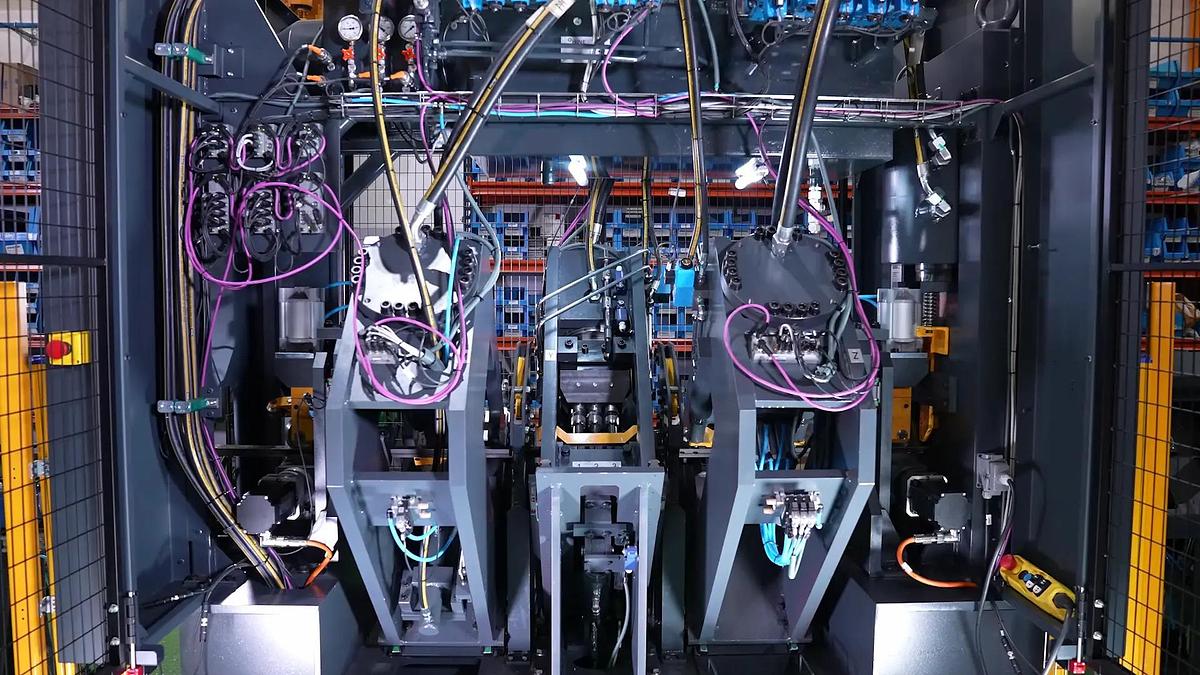

The GR series is an advanced CNC solution for punching and shearing angle profiles, designed to deliver precision, speed, and efficiency in the manufacturing of power transmission towers, steel structures, and industrial components. It is available in several models to meet different production requirements. In addition to angle profiles, the GR series is also capable of processing C-channel profiles, expanding its versatility across industrial applications. The material feeding system uses a motorized roller, ensuring smooth, continuous, and precise profile movement throughout the work cycle. The system also integrates the Zero Waste unit, which minimizes material scrap at the end of the profile and maximizes the use of each processed bar.

PUNCHING UNIT- Up to three punches per leg, providing high flexibility in production.

- Precise CNC control, with automatic positioning adjustment of the backmarks.

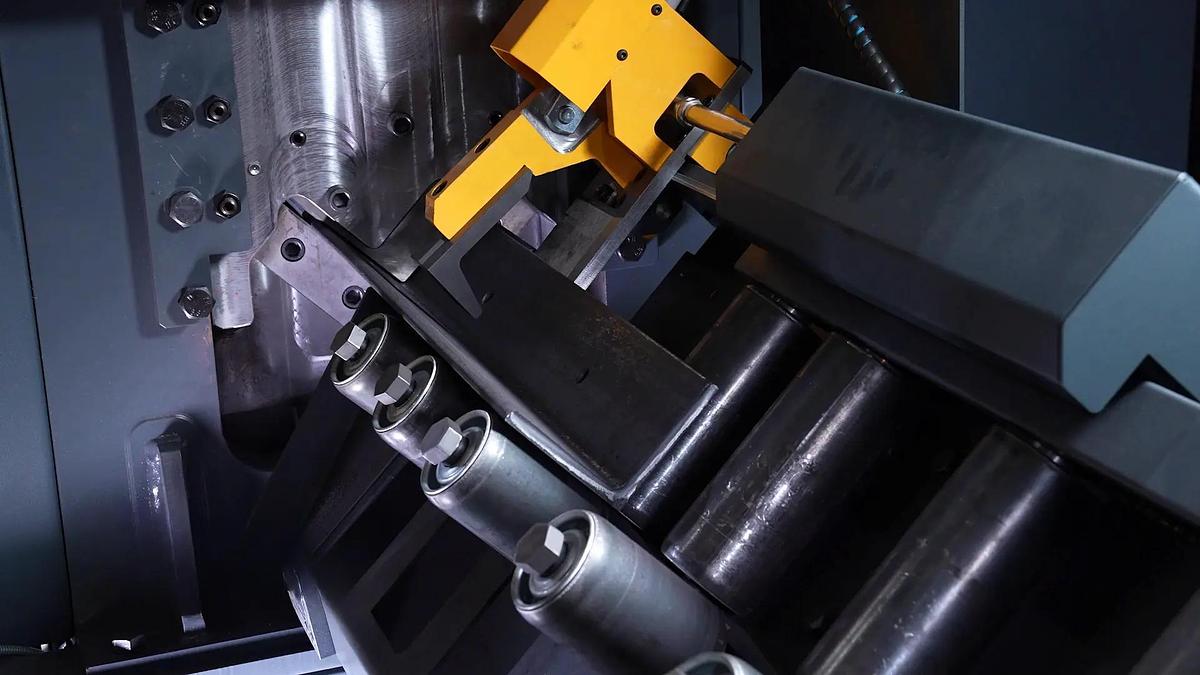

- Quick-change punch and die system, reducing tooling change times.

- 31-31-31 punching unit, allowing up to Ø31 mm punching in material thicknesses up to 15 mm.

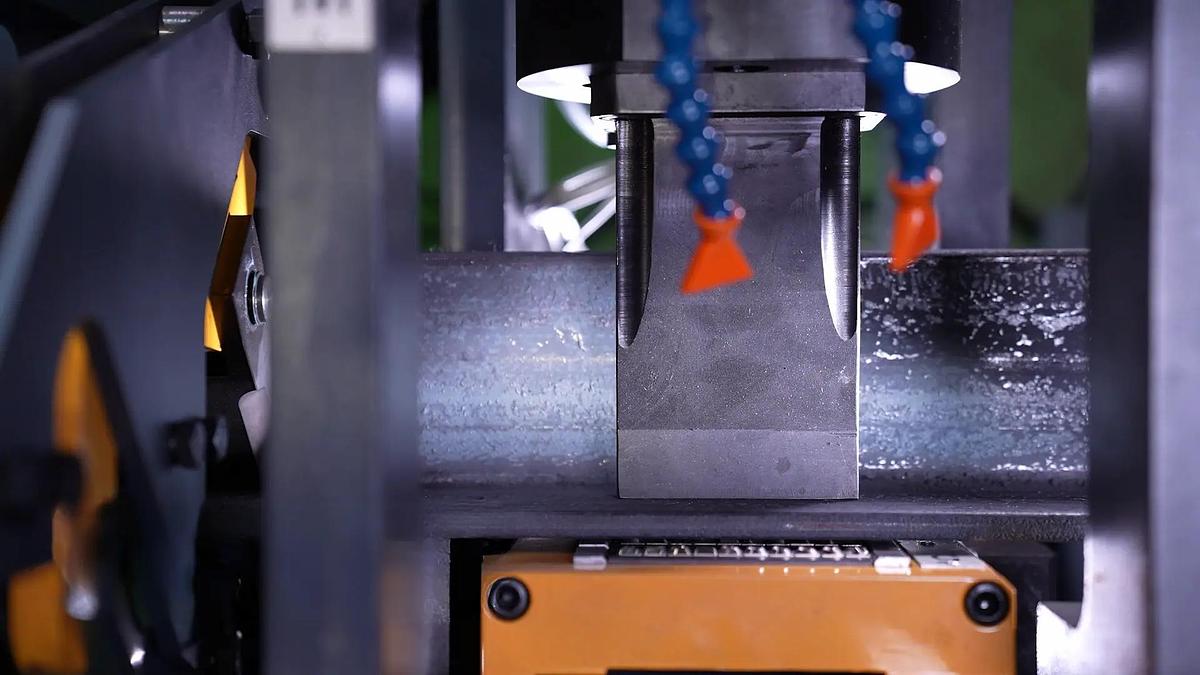

- No waste shearing station with capacity up to 250 tons.

- Quick-change blade system, with direct access to the knife holder.

- Precision angle shearing station, with adjustable stroke via CNC limit switches.

- Shearing capacity up to L-180x180x18 mm for angle profiles.

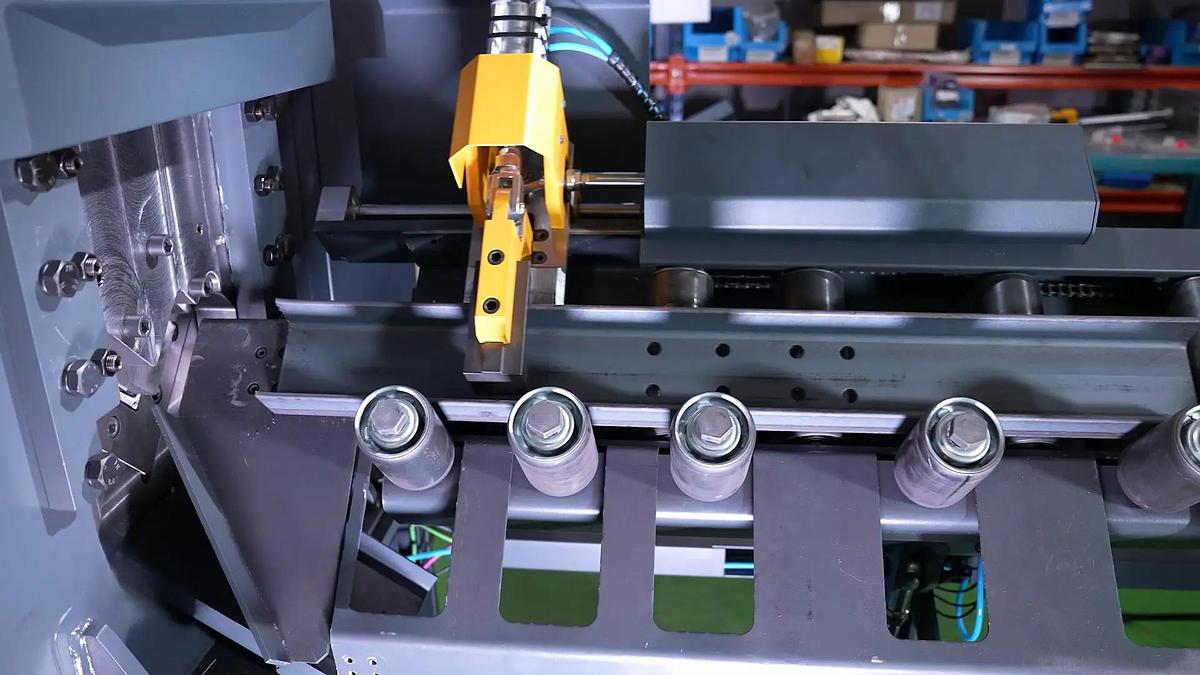

- CNC-controlled traction rollers for smooth profile movement.

- Rotary encoder measuring system, with positioning accuracy of ±0.15 mm/m.

- Adjustable material feed speed up to 45 m/min (depending on model).

- Optional roller extensions for handling profiles up to 12 meters.

- Gravity loading tables, with extended bar storage capacity.

- Automatic loading of profiles onto the infeed roller table, optimizing setup time.

- Motorized unloading of processed parts, ensuring continuous production.

- Output conveyors extendable in 3-meter modules.

- Cassette and wheel marking options available.

- Alphanumeric marking for serial numbers and part identification.

- Zero Waste System, reducing waste to 40 mm.

- Extendable loading & unloading tables in 2-meter modules.

- Hydraulic cooling system and air conditioning for extended operation.

Specifications

| Manufacturer | GEKA |

| Condition | New |

| Min Angle Size | 30x30x3 |

| Max Angle Size | 80x80x8 |

| Max Flat Bar Size | - |

| C-Channel Processing | - |

| N° Punches per Leg | 1 |

| Max Central Punching Diameter | 25 |

| Max Lateral Punching Diameter | - |

| Punching Power (tons) | 34 |

| Shearing Power (tons) | 65 |

| Material Infeed | Roller |