PCR31

PCR31

or

Call 804.598.1780

Description

Rundown

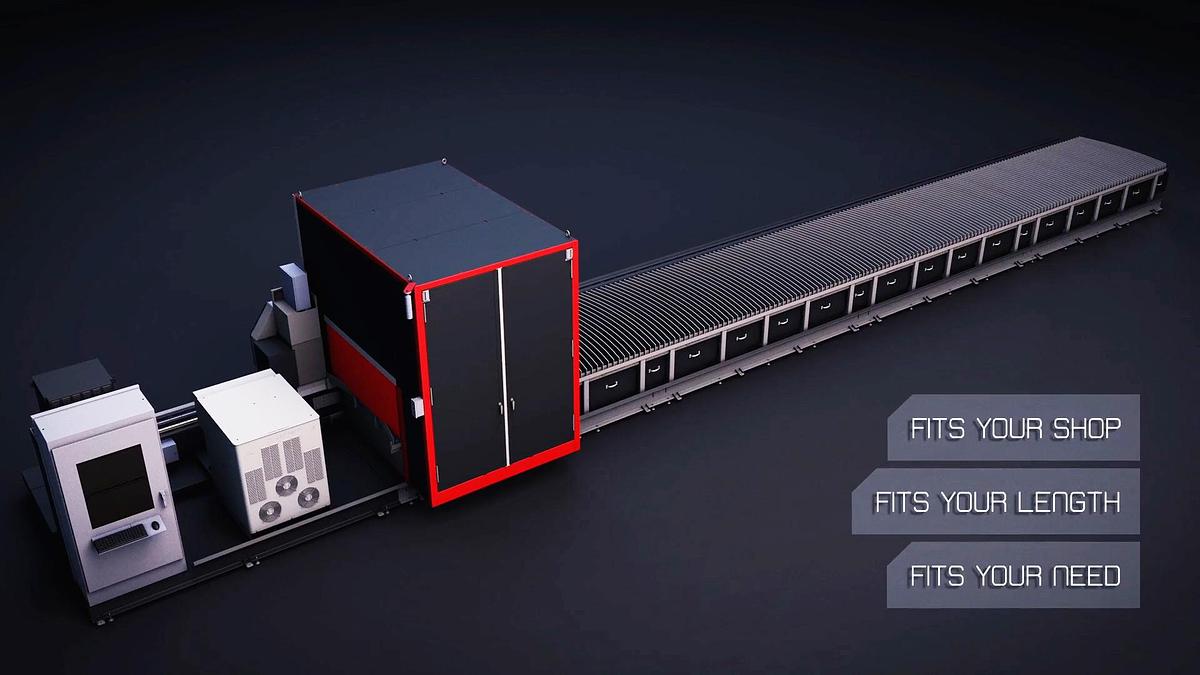

The PCR31 offers you the capability of a beam coping machine while being able to process plates in the same working space. This multi-purpose and easy-to-use machine automates all cutting operations typically performed on structural steel.

Versatility

Compact

Plate Processing

Processing Material Types, Cuts & Sizes

Types: H Beams, Channels, HP-Shape, Angles, HSS, Plate (Standard), Plate (In Option)

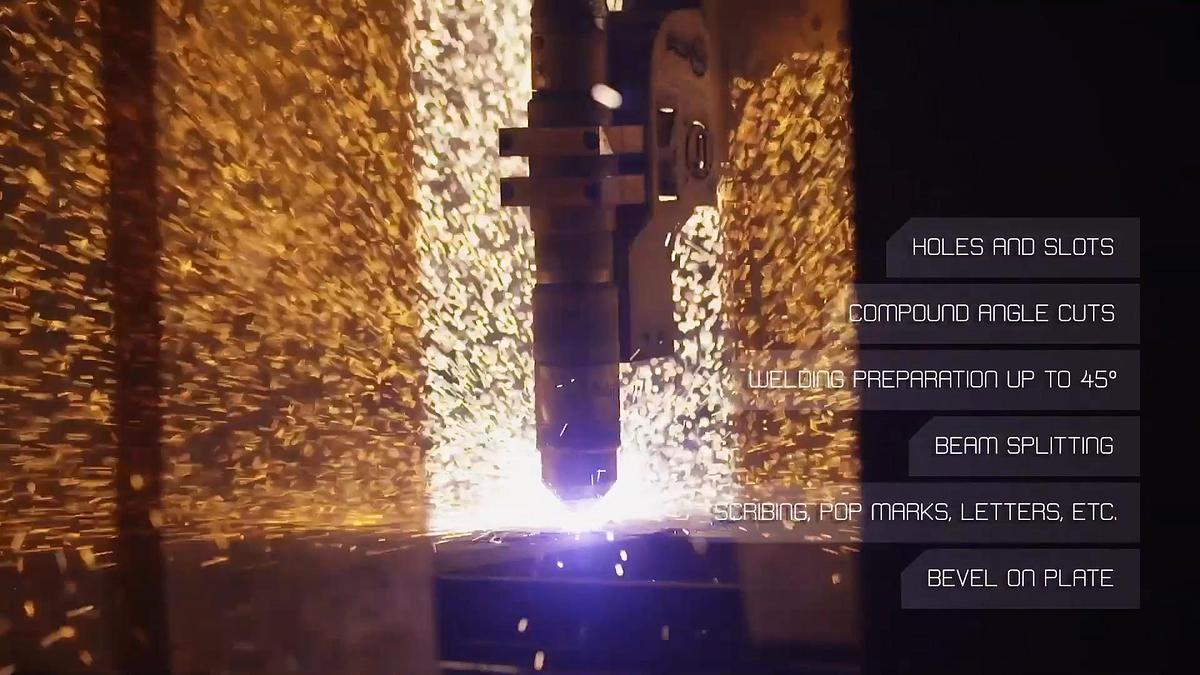

Cuts: Holes & Slots, Bevel On Plate, Compound Angle Cuts, Weld Prep (45 degrees), Beam Splitting, Scribing & Marking

**Hypertherm XPR 300 can pierce up to 1.75 ”, edge start up to 3″ Can be supplied with HPR 400

PCR31 Capabilities

Versatility

You can now work with H-beams, channels, angles, HSS and plate processing on the same system. In one operation you can prep slots, holes, copes and marking, cut notches, weld preps, split beams, scribe and mark on 3 sides.

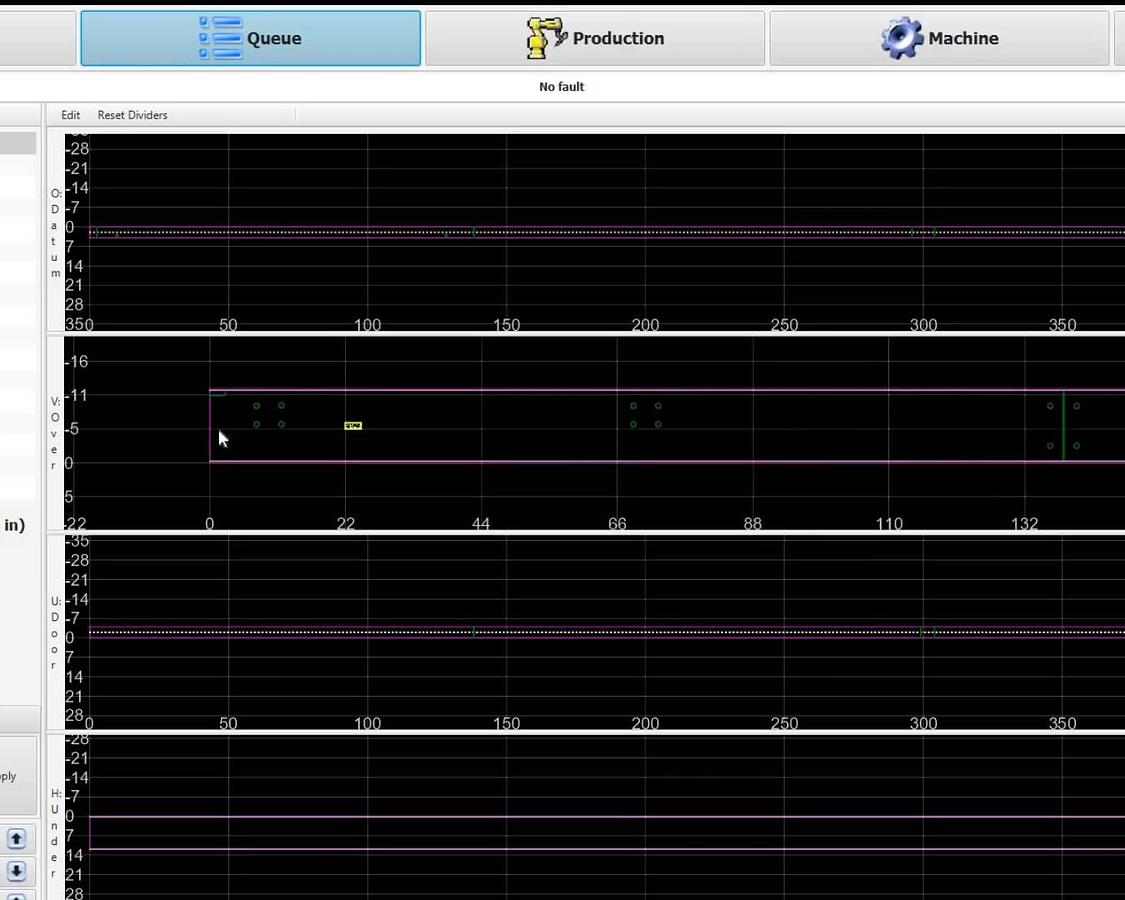

Interface

Our software is developed in-house to process even the most complex DSTV files such as DXF for plate, DSTV files from TEKLA, SDS/2, GRAITEC and other detailing software.

Plate Processing

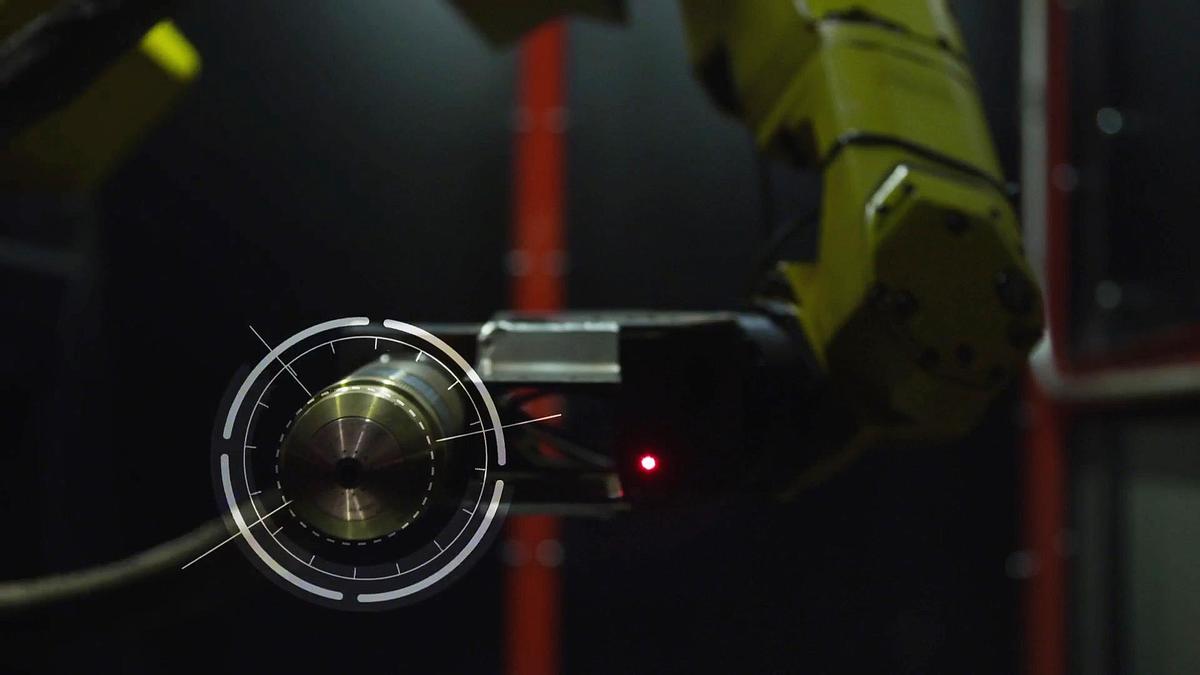

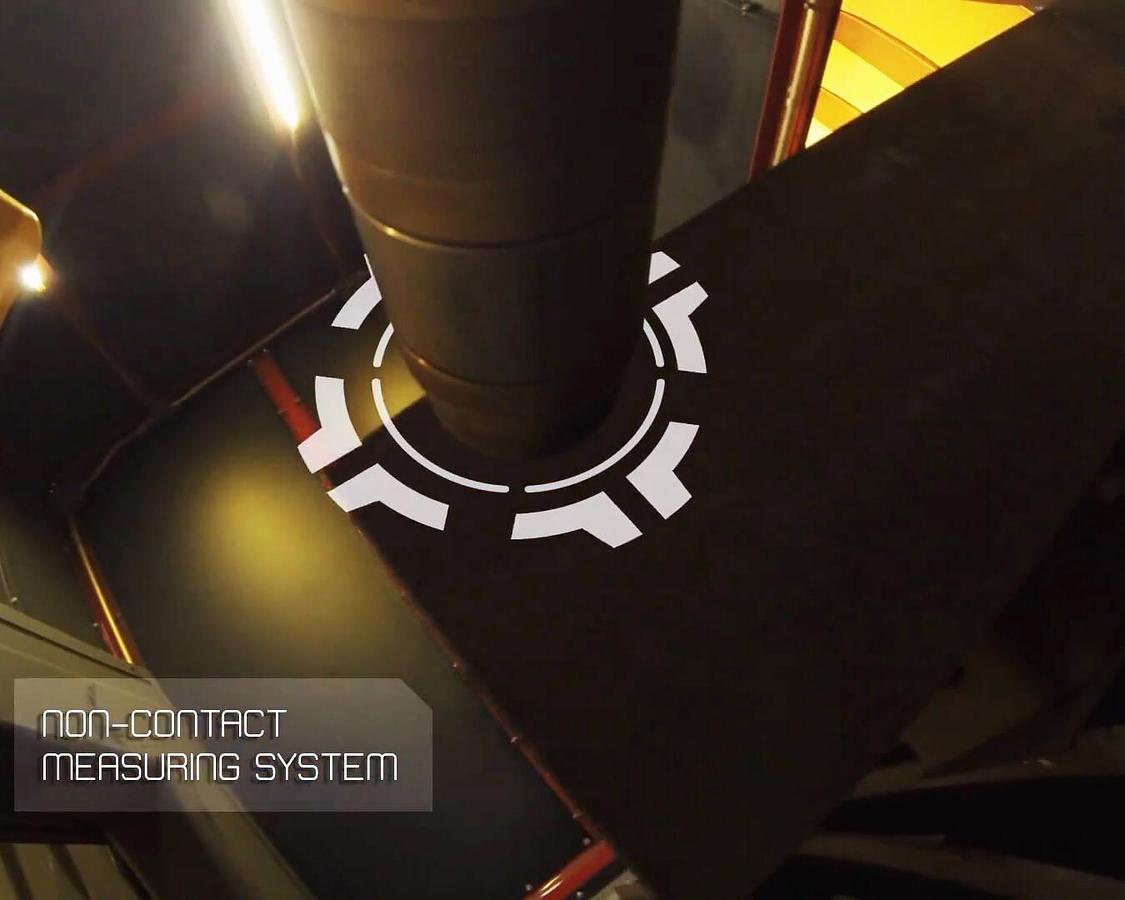

The PCR31 can process plates up to 60 inches wide. The robotic arm offers bevelling capability, including integrated torch height control, keeping control of tip to plate distance at the optimum value. The automatic torch calibration ensures the precision of bevel cut.

Accuracy & Speed

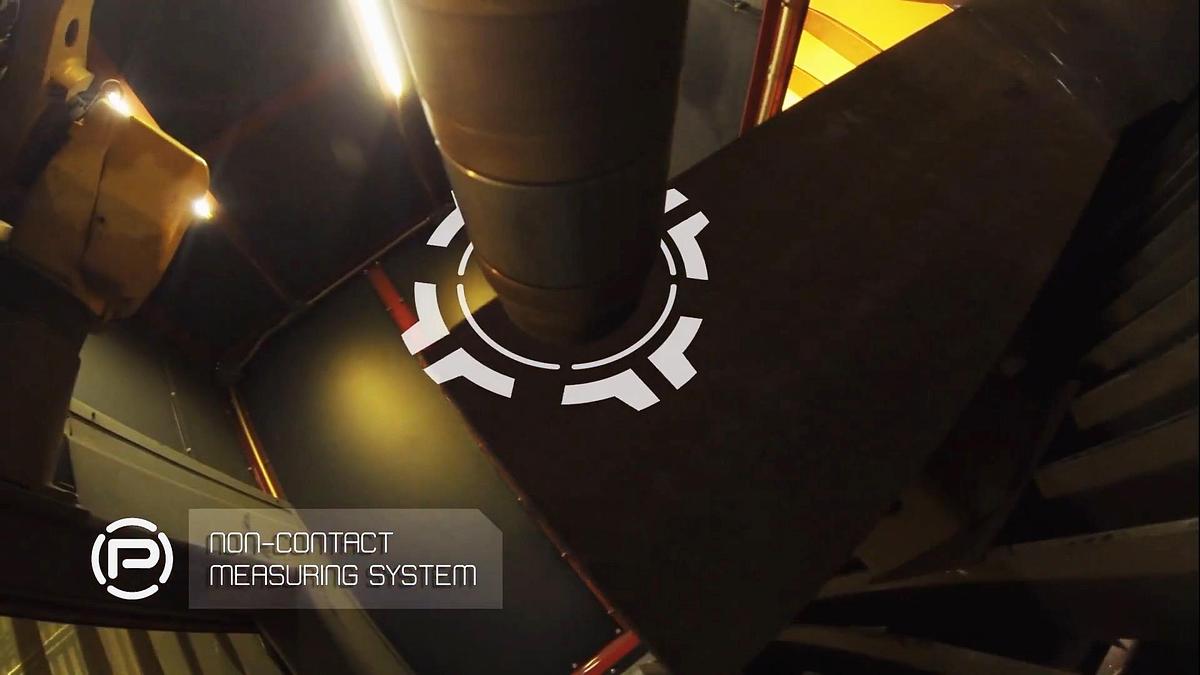

The PCR31’s 3D Vision System measures the actual dimensions of raw materials and automatically compensates for any variations, resulting in precise finished processes.

Productivity & Payback

You can nest several parts from a raw piece to reduce handling and increase productivity.

Advanced Robotic Plasma Cutting Table

Specifications

| Manufacturer | PRODEVCO |

| Condition | New |

| Sizes | I-Beam Up To 44″ & HSS Rectangle Up To 20″ x 16″ |